Automated carbohydrate synthesizer produces polysaccharides of record-breaking length

A team of researchers with members from Peking University and WuXi AppTec (Tianjin) Co., Ltd., has designed and built an automated carbohydrate synthesizer that produced polysaccharides of record-breaking length. In their paper published in the journal Nature Synthesis the group describes how they built their device and its possible uses. Hanchao Cheng and Peng George Wang with the Southern University of Science and Technology, in China, have published a News & Views piece in the same journal issue outlining the work by the team in China.

Listen this article in our podcast.

As Cheng and Wang note, carbohydrates play a very important role in biology—they are a biochemical source of energy. And as they also note, naturally occurring carbohydrates tend to be structurally undefined, which means they are made up of mixtures of molecules, making them quite complex.

For this reason, well-defined carbohydrates are prized. Unfortunately, synthesizing them has proven to be difficult, most particularly as they grow larger. In this new effort, the researchers have created a means for speeding up the process—an automated synthesizer, one that overcomes problems associated with other machines meant to do the same.

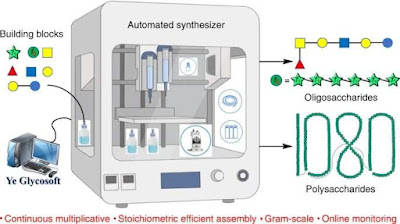

The synthesizer created by the team has three parts: a synthesizing system, a system for monitoring progress and software that is used to control the hardware. The synthesizer involves a stirrer and heat controls, and a lamp that is used to incite light induced reactions.

It also has an automated injector system for controlling the delivery of materials into the system—and an automated cleaning system to prevent contamination. The synthesizer works by computer-controlling the flow of reagents into a container and managing the growth of snake-like monosaccharides. The monitoring system continuously studies the reactions that are taking place to ensure they are being done correctly.

One of the advantages of using such a system, Cheng and Wang note, is that it has no need for protecting groups, which are masks used on reactive parts. In manual processes, such groups tend to add extra steps to the process, making it more complicated.

The result is better yields and longer glycans. Testing of the device showed it capable of creating polysaccharides made up of 1,080 sugar moieties, which included 4,320 stereogenic centers—the longest type of glycan synthesized to date. The team also used their device to create some drugs that are already on the market in a more efficient manner.

For more such news & interesting articles or how can it affect in your life subscribe to our newsletter

Comments

Post a Comment